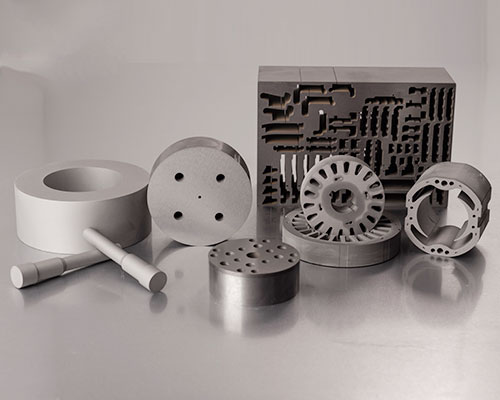

With the increase of energy saving and emission reduction requirements, powder metallurgy die process is widely used in metal products production

At present, on average, the dosage of P/M mould products in each automobile only covers 5 ~ 6kg in our country. In view of energy saving and emission reduction, more enterprises will use P/M process to produce automobile parts and parts in the future. The car chassis has a shock absorber parts, guide, piston and low seat; The brake system has ABS sensor, brake pad and so on; Pump parts mainly include fuel pump, oil pump and transmission pump key parts; The engine has a conduit, seat ring, connecting rod, bearing seat, variable valve timing system (VVT) key parts and exhaust pipe support; The transmission has synchronization hub and planetary gear frame and other parts.

With the improvement of automobile energy saving and emission reduction requirements, in recent years, VVT parts, variable pump and brake vacuum booster pump parts, these three categories of energy saving and emission reduction automobile parts have been developed and applied in large numbers.

With the development of Chinese automobile industry and the improvement of energy-saving and emission reduction requirements, more and more metal parts will be produced by powder metallurgy process; With foreign powder metallurgy companies continue to help joint venture auto plants to achieve localized production of powder metallurgy parts, the scope of domestic independent brand auto plants to use powder metallurgy parts will be more and more expanded, thus promoting the growth of powder metallurgy demand, so the demand for domestic powder metallurgy auto parts application will be greater than the growth of the vehicle market. However, it requires domestic powder metallurgy companies to continuously strengthen the management level, invest in better equipment and talents, in order to better compete with foreign powder metallurgy companies.