Application of powder metallurgy technology in automobile industry

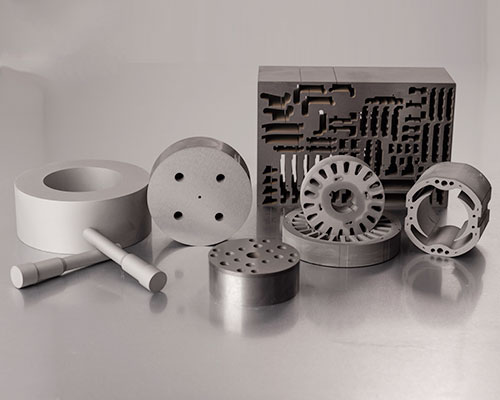

At present, the average use of powder metallurgy products per vehicle in Europe is 14kg, Japan is 9kg, the United States has reached more than 19.5kg, and is expected to reach 22kg in the next few years. At present, the average consumption of powder metallurgy products per vehicle in China is only 5 ~ 6kg. Considering the factors of energy saving and emission reduction, domestic enterprises will use more powder metallurgy process to produce auto parts in the future. Powder metallurgy die

Distribution of powder metallurgy parts in automobiles. The car chassis has a shock absorber parts, guide, piston and low seat; The brake system has ABS sensor, brake pad and so on; Pump parts mainly include fuel pump, oil pump and transmission pump key parts; The engine has a conduit, seat ring, connecting rod, bearing seat, variable valve timing system (VVT) key parts and exhaust pipe support; The transmission has synchronization hub and planetary gear frame and other parts.

With the improvement of automobile energy saving and emission reduction requirements, in recent years, VVT parts, variable pump and brake vacuum booster pump parts, these three categories of energy saving and emission reduction automobile parts have been developed and applied in large numbers.