Know these, let your mold processing handy!

In mold processing, high-quality mold products are often the perfect combination of processing equipment, tools, software and workers' skills. This paper introduces a tool handle which can have an important influence on the surface accuracy of the die processing, and a CAD software which can greatly simplify the operation steps and improve the working efficiency. I believe that such practical products will make the gold powder more handy in the future mold processing!

The TRIBOS Triangle Shank is a stress lock shank suitable for high speed machining with maximum surface accuracy. The advantage lies in its excellent continuous rotation accuracy and damping damping performance, which can ensure the smooth operation of the tool to a large extent, and avoid the micro edge breakage of the cutting tool, so as to extend the service life of the tool and enhance the performance of the spindle.

The advantages can be summarized as follows: the number of precision applications that are lost to grinding, polishing or corrosion after milling is complete is on the rise. In contrast, the tool holding system can achieve multiple functions simultaneously: ensure the tool runout accuracy, vibration compensation, ensure high geometric accuracy and perfect surface treatment. The TRIBOS triangle shank is flexible and simple, especially suitable for holding small tools and fine machining operations.

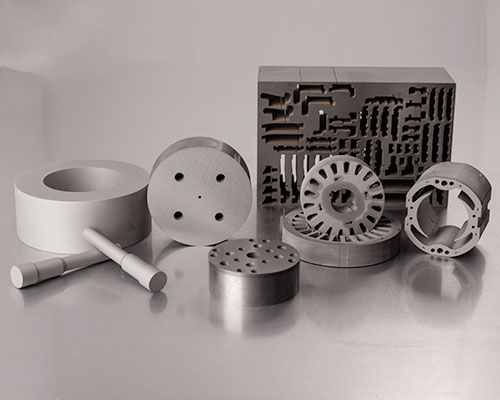

The TRIBOS-Mini can grip all tools with diameter starting from 0.3mm and shank tolerance h6. Ultra precision dynamic Balanced TRIBOS Triangle Shank instantly produces premium die for coins and MEDALS.

When applied to the die manufacturing industry, in addition to excellent workpiece surface processing accuracy, ultra-fine TRIBOS-S is also suitable for the hard to reach parts of the workpiece processing. Lightweight, slender design, high feed speed, can be used for high-speed cutting operations up to 85,000r/min. The TRIBOS extension bar is complemented by a combination of the Shukker TENDO series hydraulic shank or the TriboS-R Triangle shank. Both structures have damping effects on the whole system and thus significantly reduce vibration. It can not only replace expensive special cutting tools to process the workpiece in narrow or difficult to reach, but also ensure stability and accuracy.