Hard alloy materials for electronic progressive die

Aiming at SPCC, iron belt, copper belt, stainless steel and other electronic parts of high-speed stamping joint research and development with market users, design a reasonable process formula, in order to improve wear resistance as the goal. In stamping processing parts greatly delay wear, can prolong the service life of the die.

| series | brand | Particle size | Cobalt content (%) | density(g/cm3) | hardness | Bending strength(Mpa) | ||||||||||||||||||||||||||||||||||||||||

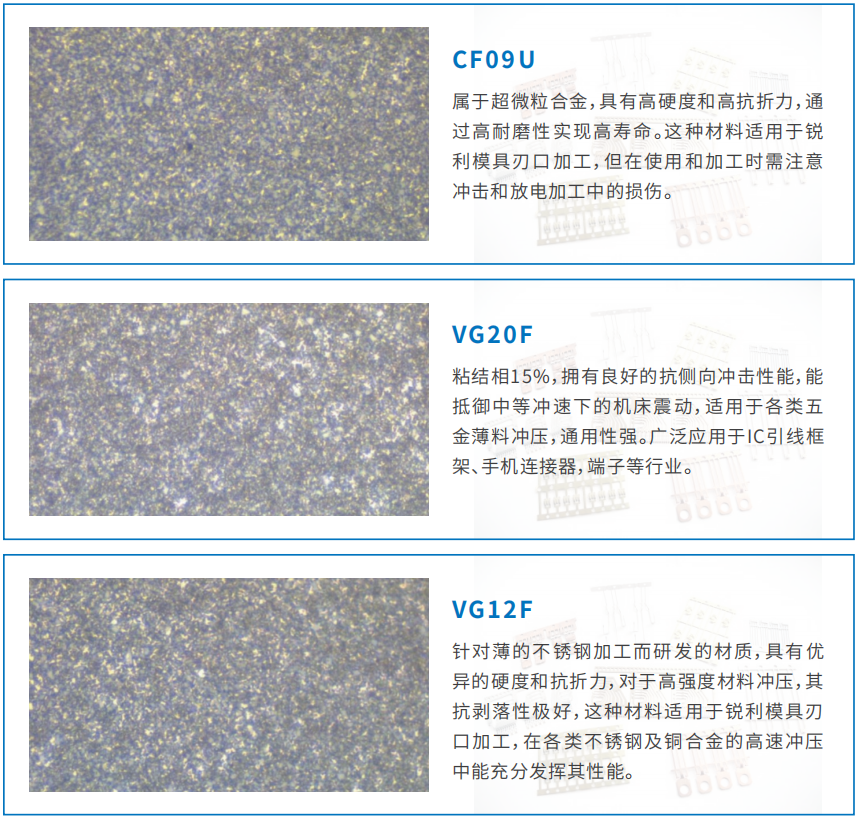

| Flaking resistance series | CF09U | 0.4 | 9 | 14.55 | 93.5 | ≥4000 | ||||||||||||||||||||||||||||||||||||||||

| CF12F | 0.4-0.6 | 12 | 14.12 | 92.5 | ≥4300 | |||||||||||||||||||||||||||||||||||||||||

| CF10F | 0.6-0.8 | 10 | 14.60 | 92.3 | ≥3800 | |||||||||||||||||||||||||||||||||||||||||

| VG12F | 0.6-0.8 | 12 | 14.13 | 91.3 | ≥3900 | |||||||||||||||||||||||||||||||||||||||||

| VG20F | 0.8 | 15 | 13.95 | 90.2 | ≥4000 | |||||||||||||||||||||||||||||||||||||||||